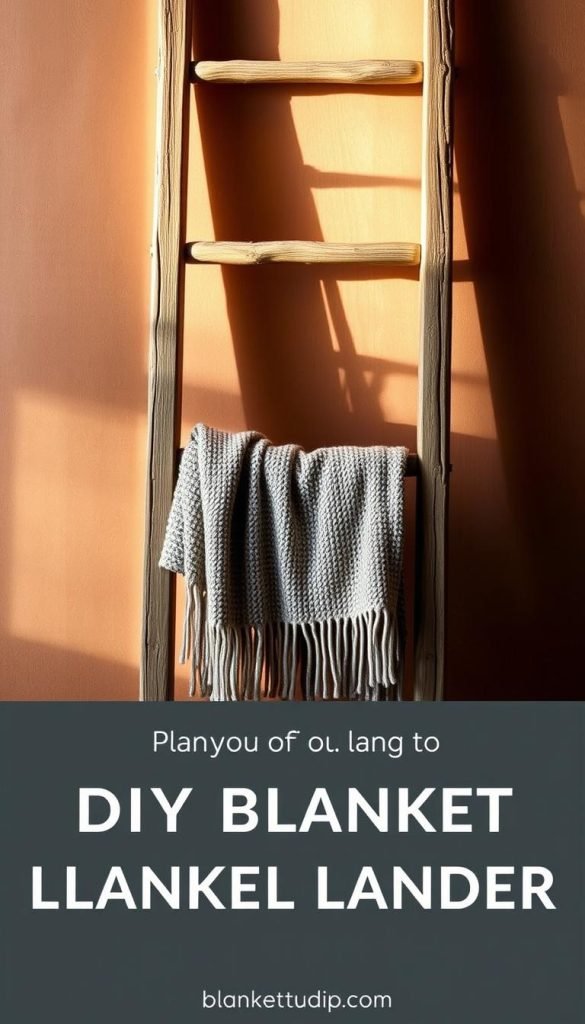

How can I turn an old ladder into a blanket rack that doesn’t wobble?

I started with a junky wood A-frame that had grime and even spiders. I hosed it down, scrubbed it, and let it dry before any work began.

Removing the top cap by tapping it from below with a hammer changed the silhouette and made the piece feel like a display instead of a tool. I trimmed rotten leg ends so the ladder would sit flat and added felt pads to feet and back to protect floors and walls.

I planned rung spacing around 12–14 inches so quilts drape cleanly. I used strong fasteners and glue, countersank and plugged holes, then stained darker while keeping some patina and sealed the wood to protect textiles.

Final touches were simple: flexible brass leg caps, a safe lean angle, and a discreet wall strap for extra peace of mind. This post shares the practical steps I used to make a stable, stylish blanket ladder from a curbside find.

Key Takeaways

- Clean and dry the piece before starting repairs.

- Remove the top cap and trim rotten ends to improve the look and balance.

- Space rungs 12–14 inches for neat quilt display.

- Use strong fasteners, glue, countersinks, and plugs for durability.

- Add felt pads, brass caps, and a wall strap for floor and stability protection.

- Finish with stain and seal to preserve wood and protect textiles.

Plan your DIY blanket ladder project the right way

Before I cut or fasten anything, I sketch the finished height and rung layout to avoid surprises. That quick sketch keeps the vintage look I want and the stable function I need.

Understand the goal: I aim for a vintage aesthetic without sacrificing sturdiness. I note final height (about 6–6.5 ft) and rung spacing (12–14 in) so quilts hang neatly and the piece reads like decor, not playground equipment.

Tools and materials I reach for

- 1 5/8 in screws, 1/4 in countersink bit, and 1/4 in dowel for plugs.

- Wood glue, 220-grit sandpaper, clamps for glue-only joins.

- Minwax Dark Walnut stain or paint and soft felt pads for feet.

I usually reuse existing wood, but I keep a 6.5 ft beam on hand if I need a new rung. I prefer vertical rungs because blankets hang straighter and the piece looks intentional.

I map a clear step sequence: clean and assess, deconstruct, repair, mark rung centers, then assemble with screws plus glue and countersunk plugs. For a full build walkthrough, I link to a detailed build guide.

How can I turn an old ladder into a blanket rack that doesn’t wobble?

I began by washing and drying the frame so I could spot soft spots and old fasteners. That simple step showed where the wood had rot and which rungs were snaggy.

Clean and assess

Remove grime and inspect carefully. I hosed the piece, let it dry, then checked joints, steps, and the lower inches of the legs for soft wood.

Deconstruct smartly

I split the A‑frame down to one side and popped off the top cap by tapping from below. I pried away old nails so parts didn’t split.

Fix weak points

Cracked or loose rungs were either sanded and re-glued or replaced. I trimmed about an inch off rotten leg ends so the frame sat flat.

Joinery, spacing, and final fit

I measured centers for 12–14 inch spacing and set rungs vertically for neater drape. For joins I used wood glue, 1 5/8″ screws, countersank holes, then capped them with 1/4″ dowels. If glue-only, I clamped each joint until cured. I kept a small box of brad nails as helpers, but relied on the screw-and-glue combo.

- Level feet and confirm lean before finishing.

- Add felt pads and optional back pads to protect walls.

- Use a discreet strap for zero-wobble peace of mind.

| Issue | Action | Tools/Parts |

|---|---|---|

| Dirty frame | Wash and dry, inspect | Hose, cloth |

| Loose or cracked rungs | Re-glue or replace | Glue, screws, clamps |

| Rot at feet | Trim and level | Saw, sandpaper, felt pads |

| Wobble | Adjust lean, add strap | Shims, wall strap |

Make it look intentional: paint, stain, seal, and style

After sanding, I weighed whether to celebrate old paint drips or to unify the surface with a darker finish. That choice sets the mood for the whole piece and affects how blankets will read on the wall.

Finish for the look you love

I kept some patina and leaned into Minwax Dark Walnut to darken and unify tones. I wiped the wood with a tack cloth after 220‑grit sanding so the stain lay down evenly.

I built color in thin coats, letting each coat flash and wiping excess for a hand-rubbed look. Then I sealed the faces so the surface felt smooth and less likely to transfer dyes to delicate blanket fibers.

Decorative upgrades

I plugged countersunk screw holes with 1/4″ dowels and a whisper of glue, trimmed and sanded them flush for a custom finish. Flexible brass sheet caps on the leg ends cost under twenty dollars but add a polished, rustic‑meets‑glam touch.

Protect precious quilts and blankets

I smoothed all snag points with 220‑grit and tested a couple quilt corners for colorfastness with a damp white cloth before hanging. I used brad nails sparingly for thin trim and kept structural joints to screws and glue so the ladder stayed sturdy.

- Wipe and seal to reduce dye transfer to blankets.

- Add felt pads to feet and back rails to prevent scuffs and micro-movement.

- Photograph your finished blanket ladder for the post and save links to the exact stain for future projects.

Conclusion

Final checks focused on fit and finish: level feet, even rungs, and a protective seal for the wood.

My checklist condensed the post into clear steps: clean and dry, remove the top cap, repair or replace soft spots, and set 12–14 inch spacing with vertical rungs.

I used predrilling, glue, countersunk screws, and neat dowel plugs for strong joins. Then I trimmed feet, added felt pads, and tested the lean with a discreet wall strap for zero wobble.

One last step was a thin coat of stain or paint and a sealer, then a quick fabric test so no dyes transfer to the blanket. This simple diy left me with a stable, stylish blanket ladder ready for everyday use.